Geotech Safety Works

GEO-TECH SAFETY WORKS |

The following Geo-tech safety works are carried out. |

|

BOULDER NETTING |

Boulder netting is a rock fall protective measure and an engineering solution adopted by KRCL as one of the safety measures. This is used at: |

|

|

Medium Strength Steel Boulder net:

Locations where it is envisaged that rock cuttings have small or medium sized boulder strata having jointed / fragmented rock structure and where there is history of small sized boulder fall cases, Konkan Railway has gone for Medium Strength Steel Boulder netting. Basically, this is a mechanically double twisted hexagonal shaped Galvanized wire mesh size of 100mm x 120mm with PVC coating. This mesh is having tensile strength of 35KN/m.

|

ROCKBOLTING |

Rock bolting has been done in tunnels and cuttings to anchor loose boulders to the parent rock and prevent them from falling. |

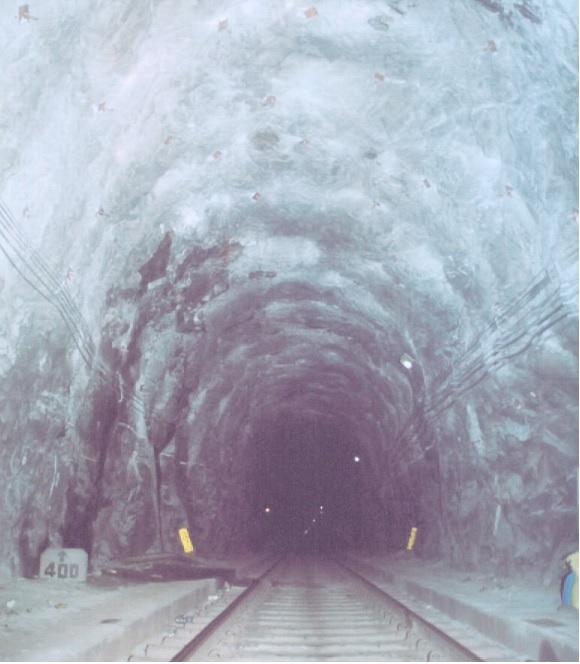

Rockbolting is a flexible rock support system which generally applied to highly jointed / blocky i.e. fair to weak quality rock strata. These rock bolts when installed in a pattern, form a zone of compression above the arch portion in case of tunnels. In this system, rock failures are prevented through the tensile loading of pattern bolts, thereby, placing the rock strata under compression and preventing the development of tension in weak rock strata. The result of rock bolting is a reinforced laminated beam that will resist sagging, falling and / or lateral movement in the rock. Various types of rock bolts like mechanical spilt bolts, bolts with resin or cement capsules, fully cement grouted bolts, etc. are used to support the rock strata. In fair and weak rock strata, 3m long, 25mm dia., TOR steel and cement capsules filled rock bolts have been used, in 1.5m to 2m staggered pattern, mostly in roof arch and also on walls in tunnel & on rock slopes in cuttings. The rock bolt support with combination of shotcrete support is provided in fair and weak rock areas. This support has prevented falling of large size boulders from roof & walls and has made the tunnels more safe |

|

ROCK BOLTING IN KARBUDE TUNNEL |

SHOTCRETING |

Shotcreting work has been done in tunnels to arrest the boulder falls and loose rocks from falling. Shotcreting is a mixture of sand, cement and aggregate upto 12mm size which is spread on the rock surface with the help of shotcrete equipment. Synthetic polyester fibres also added to enhance the cohesion and to reduce the shrinkage cracks. This is a very effective and flexible rock support system. This is highly economical compared to conventional steel support or concrete lining. When shotcrete is spread / applied with pressure on the jointed / fractured rock strata, it fills the openings like cracks, fissures, joint planes and helps in minimizing the rock displacement by way of rock mass with shotcrete. Due to exposure of rock mass to moist air and / or ground water, the rock strata gets weathered over a period of time. The weathering and more deterioration in rock strata can also be stopped by sealing the exposed rock surface with shotcrete. |

|

SHOTCRETING IN KARWAR TUNNEL |

FLATTENING OF SLOPES, CONSTRUCTION OF TOE WALL,

BALLAST RETAINER WALL, LINING OF CATCH WATER DRAINS

|

Konkan Railway is passing through a difficult terrain and on one side of the alignment is in the Western coastline of India and to the east of the line is the western ghat having a long mountain range. KRCL is having an intensive rainfall averaging nearly 3500 – 4000 mm per annum and its intensity frequently exceeding 50mm per hour. The strata in which the line is constructed is of lateritic soil, boulder mixed with soil and jointed basalt rock. There are total 564 cuttings with a cumulative length 226.71 kms. |

LATERITE SOIL – CHARACTERISTICS AND PROBLEMS

|

During construction phase of Konkan Railway the same norms as adopted on Indian Railways were incorporated namely, rock requiring blasting and soil not requiring blasting. |

Lateritic rock which required blasting, had to be given slopes commensurate with the need to blast and hence the slope were less than 1:1. Instead of adopting ¼ :1, sometimes it was ½:1 considering that lateritic rock is not the same as the hard rock. In fact laterite rock proved more difficulties to handle, requiring more blasting material. |

Cuttings are of depth varying from 10 to 45 m. In this the top layer is of lateritic soil with depths varying from the top and basalt rock strata at the bottom. In few cuttings a red bole zone exists between these two layers. Laterite is of reddish brown colour due to presence of Iron Oxides. They are very porous and permeable. Due to very high precipitation in Konkan Region, seepage of water takes place in cuttings and laterite soil absorbs water, which increases its density but decreases its shear strength. Also the presence of clay material below the top hardened lateritic mass weakens the cutting when it absorbs the water resulting in slope failure and soil slips. |

The lateritic rocks, with the lethomargic clay combinations are undergoing constant geological change, and the experience has been that the slopes are turning out to be unstable under the heavy rainfall condition. It is time that we recognize that laterite rock at the time of construction may behave as rock requiring blasting, but over a period of time years, virtually require berms and slope as if it is a simple laterite soil. |

Continuous efforts are being made to regularly inspect the vulnerable spots and stabilize them. For this purpose an expert committee consisting of three. KRCL officers are inspecting the cuttings and tunnels annually and making their recommendations for works to be taken up. Based on the recommendations for works of the above committee required works based on priority and vulnerability were completed every year. |

Research Design and Standard Organization (RDSO) team have also inspected the Konkan Railway cuttings from time to time since commencing of Konkan Railway and they have recommended remedial measures of flattening of cutting slopes and provision of berms in soil and soil mixed boulder cuttings in their various reports. However, based on priority and vulnerability, KRCL has taken remedial measures of identified vulnerable cuttings every year. |

KRCL had taken up earthwork for flattening of slopes, lining of Catch water drains and construction of ballast retainer cum drain wall. |

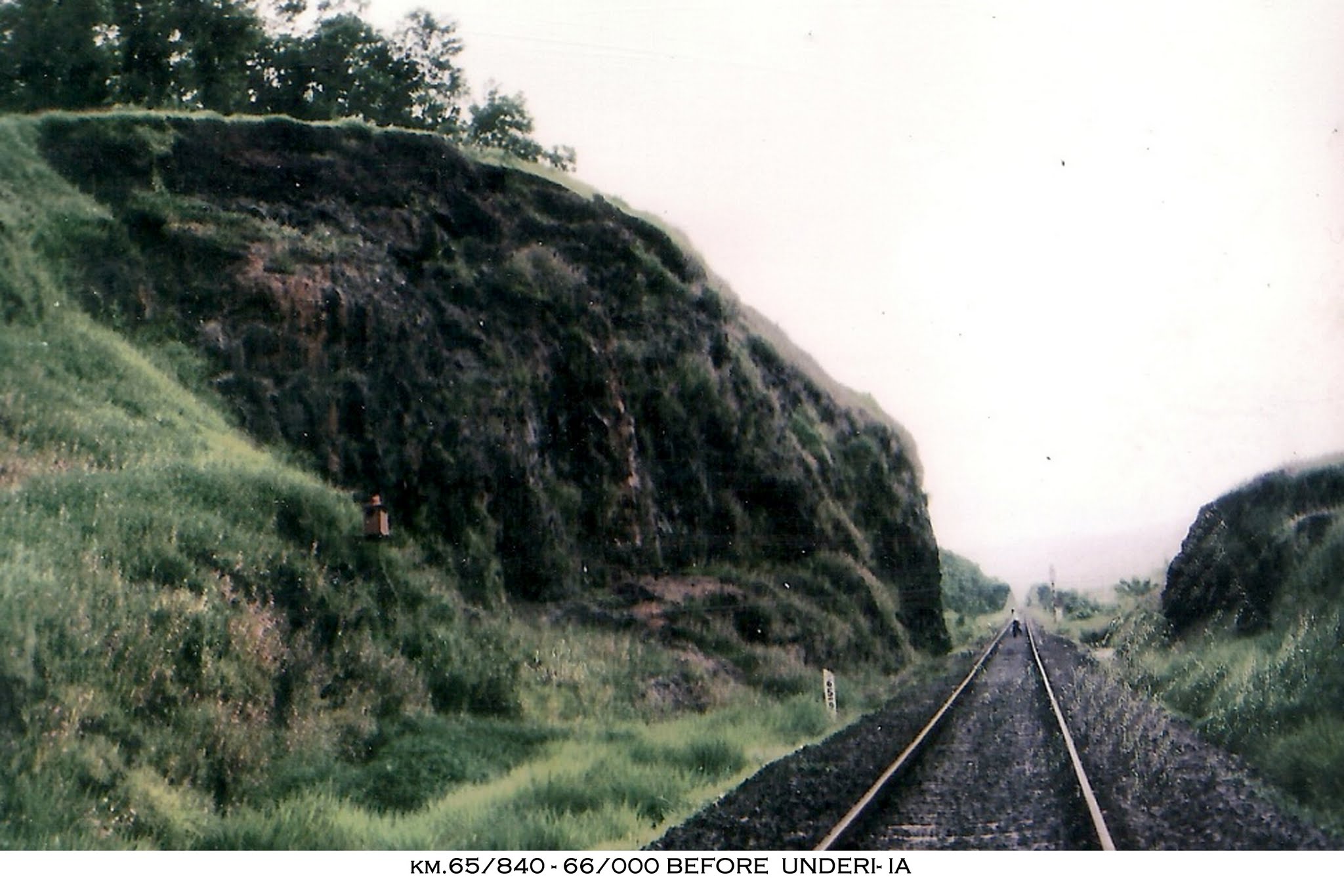

The photographs of the falttening of cutting slopes carried out in laterite cutting and in fractured / weathered rock cutting are given below: |

|

KHADEM CUTTING |

|

RAJAPUR SOUTH CUTTING |

|

CHINCHAVALI CUTTING |

PREVENTING SOIL EROSION

|

After flattening of cutting slopes in soil to 1:1 with 4-6m wide berms at every 6-8m height, grass plantation with locally available grass or vetiver is planted on the slopes to prevent soil erosion. |

|